Yanmar VIO45-5 VIO55-5 Sprocket 172119-35012 (Fit Yanmar VIO 40 VIO 45 Excavator)

Basic Info.

- Item Fit: Yanmar VIO 40 VIO 45

- Item Condition: New

- Item Weight: 105 lbs

- Item Maker: FLundercarriage

- Place of Origin: Quanzhou

Delivery Info.

- Inventory Class: Standing

- Packaging: Carton/Pallet

- ETD: 24-72 Hours

- ETA: 5-30 Days

- The sprocket is meant for individual sale, unless it's part of a bigger set or full undercarriage kit.

- It works just like the original part that came with your excavator and will fit perfectly.

- This particular sprocket, with nine bolt holes and nineteen teeth, is made only for certain Yanmar models and won’t fit other brands.

- We use top-quality materials and special hardening techniques on the teeth for extra durability.

- You can trust it for your excavator's needs.

- Yanmar B50

- Yanmar B50-1

- Yanmar B50-2

- Yanmar B50-2B

- Yanmar B50V

- Yanmar VIO40-2

- Yanmar VIO40-3

- Yanmar VIO45-5

- Yanmar VIO50-2

- Yanmar VIO55-5

- The Yanmar part number is the same: 172119-35012.

- The sprocket is hardened in one process to make it tough without being brittle.

- Our aftermarket sprockets match the quality of the original parts but are more affordable.

- Installing the sprocket should be done manually, following the tightness guidelines from Yanmar.

294 in stock

Share This Product

Flundercarriage Show

Why Choose FL Undercarriage

-

20+ Years Experience

-

100+ Dealers Globally

-

300000+ stock Keeping units

-

50000000+ USD Annual sales

Product Range

Our sprockets are built to withstand extreme conditions, ensuring smooth and efficient power transmission in your machinery. Crafted from high-quality materials, they offer exceptional wear resistance and durability, making them ideal for heavy-duty applications. Trust our sprockets to enhance the performance and longevity of your equipment, keeping operations running smoothly.

Machinery brands our parts are suitable for Bobcat, Caterpillar, Case, Doosan, GEHL, Hitachi, Hyundai, IHI, Kubota, Kobelco, Komatsu, Pel-Job, Takeuchi, Volvo etc.

How are your sprockets produced

Trade Show Events

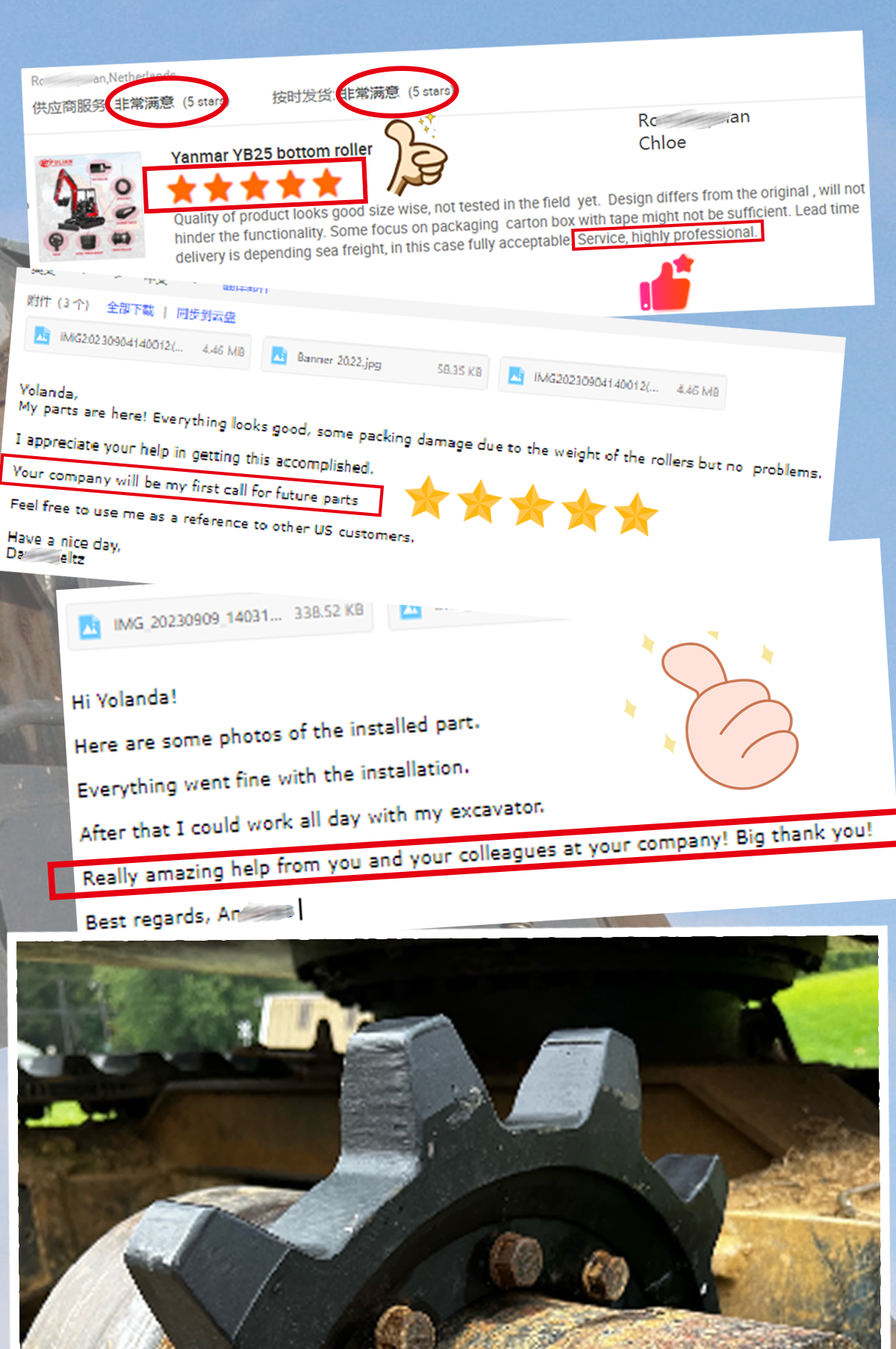

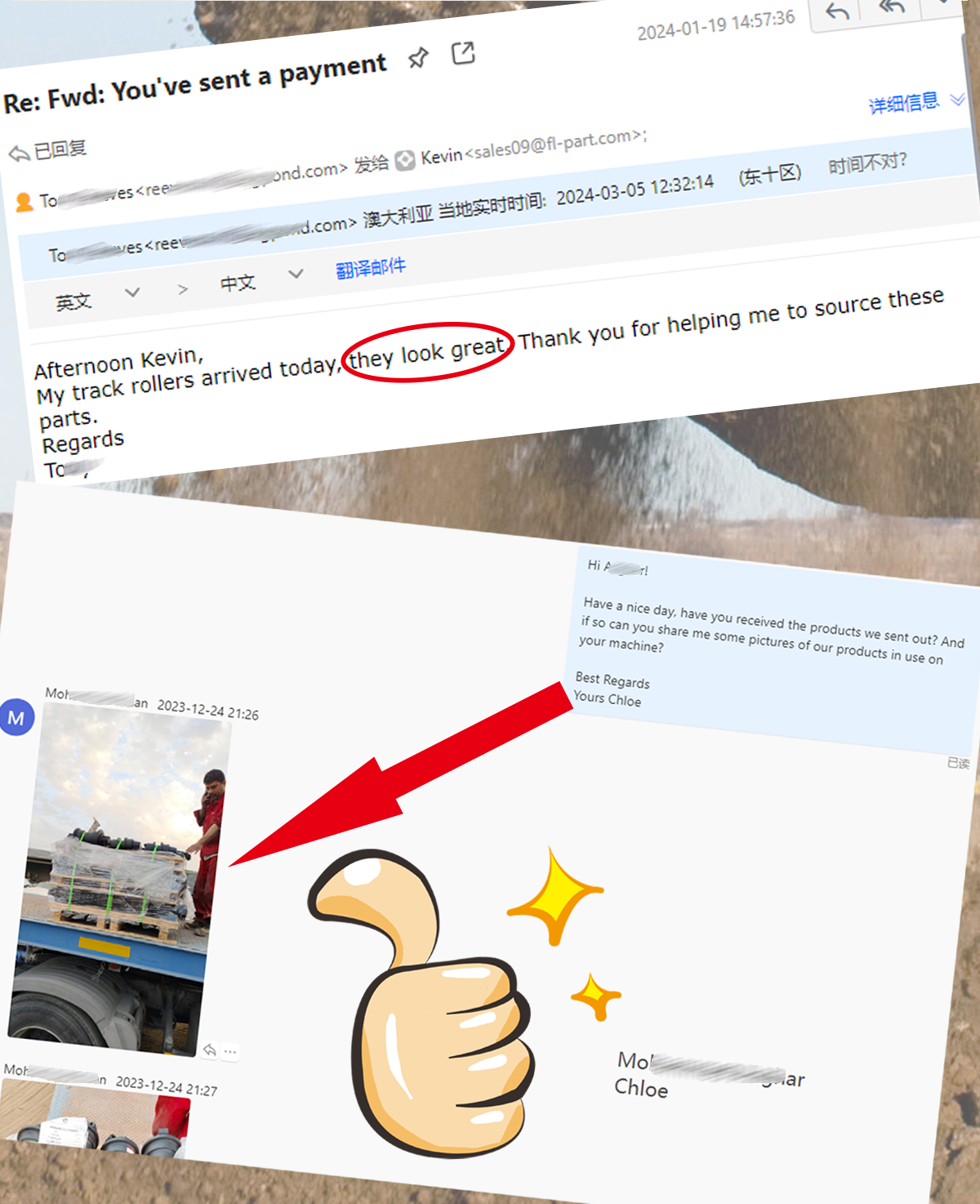

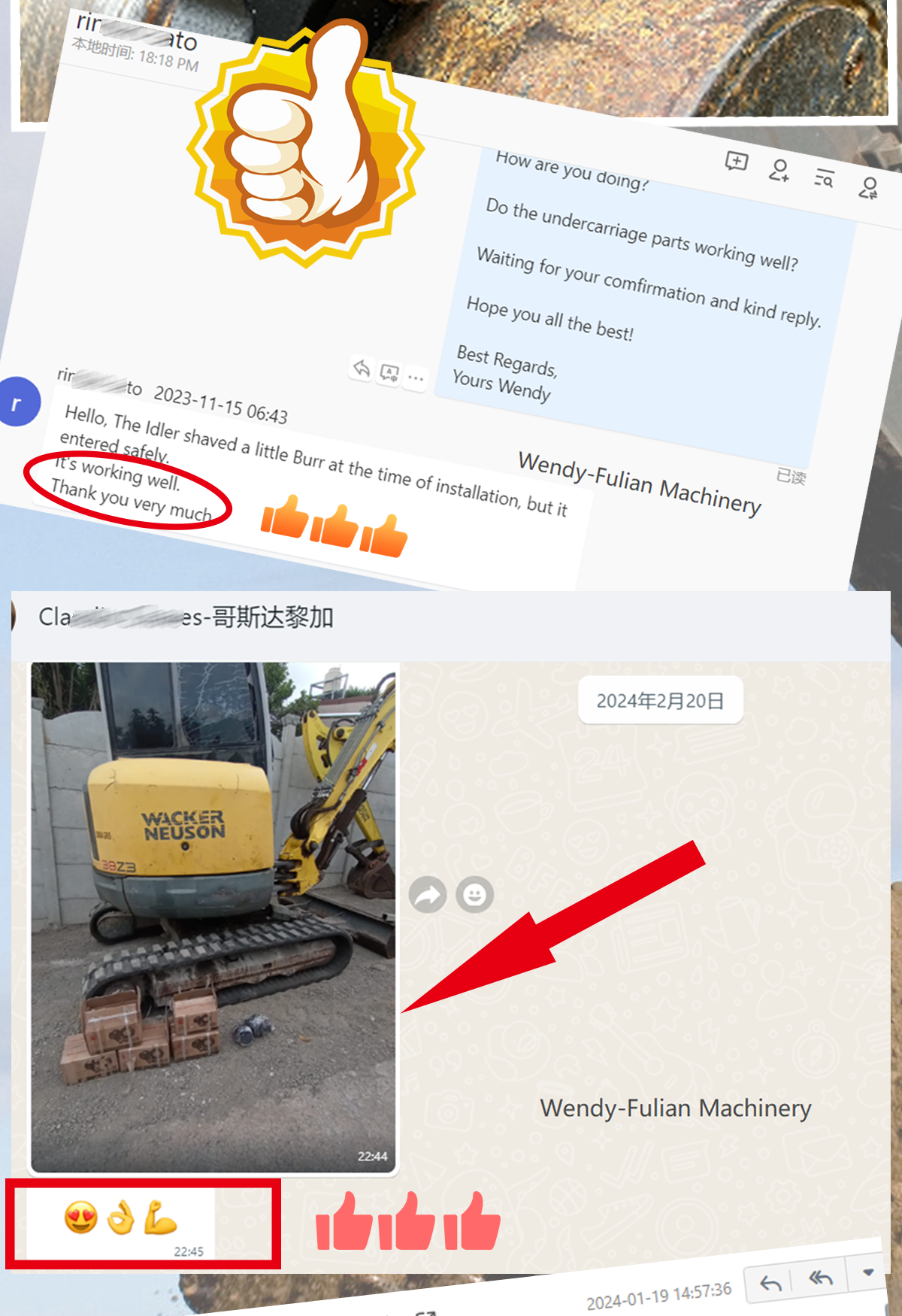

Customer reviews

FAQ

How often do excavator sprockets need to be changed?

A sharp gear indicates that the gear is worn. Check whether there are grooves around and under the gear that are similar to the chain shape. This "shadow" wear indicates that the gear has been seriously worn and should be replaced.

What are the contributing factors that lead to the deterioration of sprockets on an excavator?

Several factors lead to wear and tear of excavator sprockets, including:Heavy usage, Abrasive environments, Improper track tension, Inadequate maintenance, Rough operation, Quality of the sprockets, Misalignment of components, Age and metal fatigue

What maintenance routine can I follow to ensure my excavator sprockets last longer?

To extend the life of your excavator sprockets, implement a maintenance routine that includes:Regular cleaning of debris and dirt,Frequent inspections for wear,Ensuring correct track tension,Prompt replacement of worn parts,Lubrication to reduce friction,Using high-quality replacement sprockets,Operator training to prevent harsh handling.